|

INSTRUCTIONS OF PRESSURE GAUGE |

|||||||||||

| Mounting | |||||||||||

| Different types of cases are possible according to position of the connection. | |||||||||||

|

|||||||||||

| Position | |||||||||||

|

|

|||||||||||

|

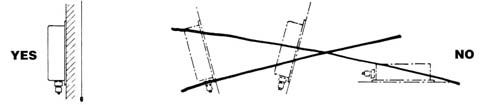

Always vertical, otherwise specify the direction and angle. |

|||||||||||

|

|||||||||||

|

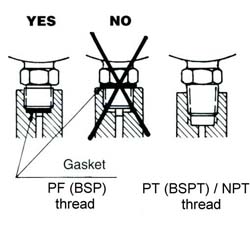

Threads Standard threads are: Taper PT (BSPT) or Taper NPT or Parallel PF (BSP) |

|||||||||||

|

Parallel PF (BSP) Place a gasket between the end of the thread and around the spigot. |

|

||||||||||

|

Taper PT (BSPT) or Taper NPT Tightness is achieved metal on metal without any gasket. However, a seal tape wound around the thread prevents leakage and provides a better tightness and makes the screwing easier. |

|||||||||||

| Oxygen | |||||||||||

| For oxygen service, the parts of gauge must be oil-free. Specify by ordering. | |||||||||||

| Installation | |||||||||||

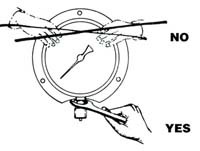

| Never install the pressure gauge by turning the case but mount it with a wrench by means of the hexagon or flats provided on the socket. |

|

||||||||||

| Isolating Cocks | |||||||||||

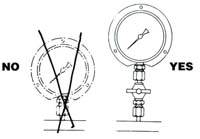

| A pressure gauge must never be mounted without an isolating cock. |

|

||||||||||

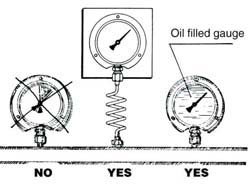

| Vibrations | |||||||||||

|

Vibrations of the pressure gauge must be avoided to prevent excessive wear of the mechanism. It would be better to set the gauge on a rigid support on which the vibrations of the pipe have no influence. If this mounting is impossible, choose the pressure gauge with liquid filled. A flexible small diameter capillary can also be placed between the gauge and diaphragm seal. A capillary can also be used as a vibrations or pulsations damper. |

|

||||||||||

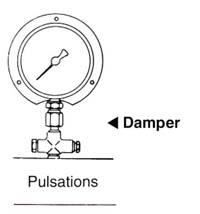

| Pressure Pulsations | |||||||||||

|

In the case of pressure measurements of pulsating fluids, a damper should be fitted between the pressure gauge and the pipe. Adjustment of damper will be done on line where the gauge is used, according to the pressure pulsations. |

|

||||||||||

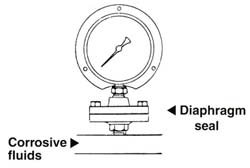

| Corrosion | |||||||||||

|

If stainless steel do not provide sufficient guarantee against corrosion, place a diaphragm seal between gauge and pipe. Parts of the diaphragm seal in contact with fluid (lower flange and diaphragm) are made of a material withstanding corrosive fluids: stainless steel, PP, PVC, PTFE, PVDF…etc. or coated with corrosion-proof materials (Teflon, halar, Kel F…etc.). |

|

||||||||||

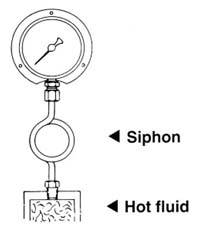

| Temperature | |||||||||||

|

Excessive temperatures must be avoided. |

|

||||||||||

| Full Scale Range | |||||||||||

|

The full scale range of pressure gauge should be 1.5 to 2 times of maximum process pressure.

|

|||||||||||